How do protein skimmers work and how to choose one?

Protein skimmers utilize different designs and methods to remove the dissolved organic wastes, all with claims of efficiency and ability. So, it is hard to determine which design is the right one for your system and this article is intended to help you make the right decision.

- What is a protein skimmer?

- How does it work?

- What is an efficient skimmer?

- Types of protein skimmers

- How to choose the most efficient protein skimmer?

What is a protein skimmer?

A protein skimmer is a piece of equipment used in aquariums, especially marine and reef tanks, to physically remove organic materials from the aquarium water.

In the open system of the ocean, organic waste products are removed and diluted to a level where they don’t cause harm. An aquarium is a closed system where these same organic materials and their breakdown compounds can quickly accumulate to a level that adversely affects tank inhabitants, especially corals.

These organic materials include the waste products from invertebrates and fish and the decay products from dead organisms and uneaten food. Proteins are one of these organic materials hence the general industry name, protein skimmer. Collectively these by-products from the breakdown of biological materials are called Dissolved Organic Compounds (DOC’s). Protein skimmers are used to help remove these dissolved waste and organic materials.

Protein skimmers improve water quality in a number of ways including reducing algae build-up, reducing phosphates, removing toxins released by corals and invertebrates, reducing water change frequency, increasing oxygen in the water, and increasing water clarity.

How does it work?

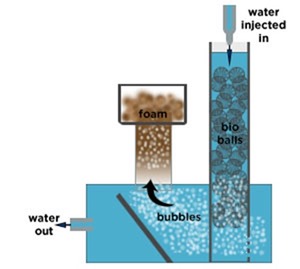

Protein skimmers work by a process called foam fractionation and are sometimes called foam fractionators. They originated in the waste-water treatment industry as a way to reduce the organic load before the water reached the activated sludge reactors.

The process takes advantage of the attraction between organic waste and air bubbles. When water full of dissolved organic compounds, is put in contact with a column of air bubbles, the waste products stick to the bubbles creating foam which is then collected and removed.

The very simple chemistry behind this is that DOC’s are bipolar molecules, that is they carry charged (polar) and uncharged (non-polar) regions. These polar and non-polar areas are attracted to the air/water interface of the bubble as it moves upward through the column of water.

As these DOC studded bubbles get to the top of the skimmer they accumulate creating stable foam bubbles that take a long time to ‘pop’. The result is the DOC’s slowly concentrate at the top of the skimmer in the foam which accumulates and slowly gets pushed into a collection cup.

What is an efficient skimmer?

Efficient skimming comes about when the water level and bubble flow in the column produce a foam with a fairly stiff consistency that accumulates at the top and overflows into the collection cup. The effectiveness of a skimmer is based on:

- The amount of bubbles produced: More bubbles means more interactions.

- The size of the bubbles produced: Smaller is better, in a range of 0.5 – 1 mm. Smaller bubbles provide more surface area for reacting because more will fit in a given amount of space and so collect more DOC’s than larger bubbles. It is also easier to keep smaller bubbles from rising too swiftly in the reaction chamber giving them more time to react.

- The contact time the bubbles have with the water: Termed dwell, the longer the contact between the bubbles and the water the more time the two have to react with each other.

- The total amount of water it will process.

- The turbulence created inside the reaction chamber: The design can adversely affect the protein carrying bubbles, bubbles crashing into each other can dislodge accumulated DOC’s from the bubbles and make the skimmer less effective.

- The stability and ease of removing the foam produced: The bubbles creating the foam need to remain stable long enough for rising bubbles to make a foam (termed ‘dry’ foam) that slowly flows into the collection cup. Foam bubbles that break quickly upon reaching the top of the reaction chamber (termed ‘wet’ foam) can deposit most of the DOC’s right back into the water instead of the collection cup.

Types of protein skimmers

Air-driven skimmers

These were the first types introduced to the hobby. They can be gravity or pump fed and as in-tank, independent units, or hang-on designs. They are for the most part inexpensive and easy to install with many DIY plans available. They can be very efficient at removing DOC’s but do require regular adjustments and maintenance such as replacing air stones and air pump diaphragms, both an ongoing expense.

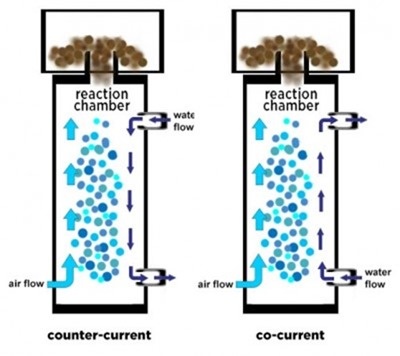

You can break down air-driven protein skimmers into two general types based on the direction the water and bubbles move in them. In a counter-current system, the air bubbles flow against the direction of the water flow. In a co-current flow system, the introduced air and water travel in the same direction within the reaction chamber.

Counter-Current (CC) Air Skimmer:

This style has water pumped in at the top of the cylinder where it is directed downward at about a 45-degree angle to make the water swirl. Wooden air diffusers (airstones) and a powerful air pump produce bubbles that rise upward. DOC’s stick to the bubbles and accumulate as foam in a cylinder neck.

This is the original design first used in home aquariums and is a common type for those who like a DIY project as they are easy to construct. A minimum recommended height is 28 inches with two to three air woods for every 4 inches of column diameter.

- good foam production with properly functioning air stones,

- good bubble size,

- maximum contact time (with taller units)

- frequent maintenance in pumps and airstones,

- recurring costs,

- frequent tuning (water height adjustment in the reaction chamber)

Co-Current (CC) Air Skimmer:

These have an air source with an airstone or similar diffuser at the bottom of the reaction tube. The water is drawn up into the chamber in the same direction. The air and indrawn water combine as they rise in the chamber. Usually found as a hang-on or in-tank installations.

- suitable for small (less than 30 gallons) low capacity systems,

- good for beginners as easy to operate

- minimum dwell time,

- dependent on the quality of the diffuser and the pump used,

- frequent maintenance

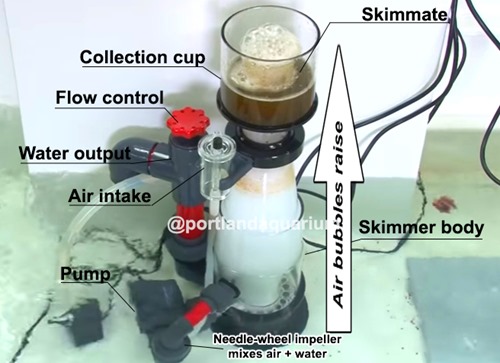

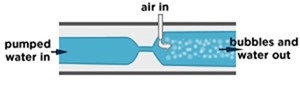

Venturi skimmers

This style uses a venturi injector and a powerful pressure pump to drive the venturi valve to create tremendous amounts of bubbles. The venturi valve delivers the water being treated as well as creating millions of microscopic bubbles.

Venturi valves work by taking the high-velocity water pumped into the valve’s main body, pushing it through a choke-point where a nipple allows room air to be drawn into the valve and then injected into a swirling jet of water which is shot into the skimmer’s reaction chamber.

Higher-end units often come with a threaded needle-control valve to fine-tune the amount of air injected. There is generally less maintenance and adjustment in this type since the water pump drives both the air and water flow (co-current). When first introduced this design was popular because of its compact size and high efficiency. As skimmer designs have evolved, you are more apt to see a venturi valve as a part of other skimmer designs.

- good water flow,

- good foam production,

- moderate contact time,

- eliminates air pumps and airstones

- requires a powerful pump,

- pump requires regular maintenance,

- valves can clog

Needle wheel skimmers (most popular these days)

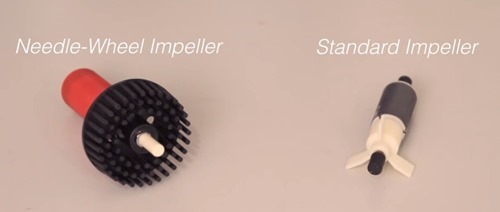

Also known as aspirating, air shredding, or mesh wheel skimmers. These draw air into the impeller cavity

of a powerhead or small pump to creates bubbles. The bubbles are chopped up into smaller bubbles by an impeller, specialized needle wheel, or pegged wheel.

They have a very slow water flow and use low power pumps which makes them less expensive to operate. They are able to generate large amounts of foam. Because the needle wheels are a patented design, there is a wide range of price and effectiveness. Higher-end models tend to be very effective and easy to clean and adjust so model research is imperative.

- good foam production,

- good bubble size,

- excellent contact time,

- efficient to operate,

- smaller size

- some needle wheel impellers can be prone to higher failure rates,

- damaged ones expensive to replace or repair

Downdraft skimmers

One of the most powerful types of skimmers is a design that is neither counter-current nor venturi, it also referred to as Environmental Tower Scrubber (ETS).

A jet of water is sprayed under high pressure into a narrow column (tower) containing plastic media balls. The water crashing through the balls creates thousands of ultra-fine bubbles. These create a very effective foam that is channeled into a box below where it allows time for the DOC rich froth to rise up into a wide-mouthed tube and into the collection cup above it.

Beckett skimmers are an evolution of the downdraft skimmers utilizing a Beckett nozzle (patented foam nozzle) instead of media balls to create foam.

- good water flow,

- excellent bubble production and contact time,

- can process large volumes of water,

- suited for large systems and systems with large bio-load

- tend to be large and bulky,

- requires powerful pumps,

- difficult to clean,

- expensive to purchase and operate.

Spray injection skimmers

These look like smaller downdraft designs but use engineered injectors to create foam. Smaller in size than comparable Downdraft and Beckett skimmers and they use smaller pumps making them more user-friendly and affordable than comparable styles. They are also some of the easiest skimmers to adjust and maintain.

- excellent bubble and foam production,

- smaller size but with the performance of a larger unit

- expensive,

- noisy.

How to choose the most efficient protein skimmer?

Which skimmer to purchase entails evaluating all the various choices for compatibility with your system; how much effort and time you want to put into getting and keeping it at peak performance, and how much you have to invest in the cost of the unit, running it, and maintaining it. You should consider the following conditions as you research and shop:

The bio-load

- What’s in your tank: Tanks with fish generally have higher DOC loads.

- Tank volume: Some skimming methods are more suited to smaller volume tanks, some to larger. The larger the amount of tank volume to skim, the wider the skimmers reaction chamber diameter should be.

Skimmer efficiency

A protein skimmer’s efficiency depends on how hard the bubbles are forced into the water and the amount of time the bubbles spend in the chamber. Also in play is the volume of bubbles produced, the water to air ratio, the volume of water processed, and turbulence inherent in the design.

- Reaction chamber height: The taller the reaction chamber, the longer the contact time between the water and the air. Choose a unit that maximizes this for your setup.

- Water flow through the skimmer: The water flow rate and its direction through the skimmer need to be such to allow the air bubbles and DOC’s in the water to react. Also where the water is being drawn from influences efficiency as the surface layer of the water in your tank contains the greatest concentration of DOC’s.

- Amount of air pumped into the reaction chamber: The volume of air pumped into the reaction chamber helps create and maintain bubble size and reduces potential turbulence of the air bubbles.

Placement

Skimmers can be placed in the sump, hang on the sump, in the tank, hang on the tank, or be free-standing. If you already have a system set up, placement is the first consideration.

To be most effective a protein skimmer should be the first step in your filtration process; any pre-filter or other mechanical filtration that comes between surface-collected water and the skimmer seriously compromises its performance.

If you have a wet/dry filter, an in-sump skimmer can be the easiest and most cost-effective. If your sump does have that much space, an external model that sits next to the sump is an option. Both these have the advantage of being out of sight, are less likely to be bumped.

If you do not have a wet/dry filter, then an internal or external hang-on-the-tank model will work depending on the space behind your aquarium or how much space in the tank you are willing to give up.

Undisturbed surface water

The DOC’s you want the skimmer to remove are attracted to the thin, top layer of the water’s surface in the aquarium. For the most efficiency, flow into the skimmer should include as much of this concentrated, undisturbed, and raw water from the surface.

Sump model skimmers generally receive water from built-in overflow boxes, bulkhead fittings, and other surface draining methods. Hang-on skimmers may include surface extraction boxes that force it to draw this top water layer from the aquarium.

Easy to maintenance

All skimmers require cleaning to work their best. No matter what skimmer you choose, its efficiency will decrease if not properly maintained. Collection cups size influences how often you have to empty it; a built-in drain lets you hook up a larger container and empty it even less often.

Look at the design to see how easy it is to access parts that may need replacement or cleaning. How much time you want to spend maintaining your skimmer is an important factor in selecting the right one for you.

Cost

A skimmer purchase is not the piece of equipment to skimp on; get the best one you can afford as you don’t save any money when you find it inadequate and need to replace it. Think of the skimmer as a small percentage of the total investment to maintain a healthy system. Selecting one that is slightly larger than necessary is better than choosing one that is too small.

Consult experienced hobbyists

Before you buy, talk with your local fish store and solicit options from their professionals. Seek out experienced hobbyists (through local clubs, aquarium societies, online forums) for insight and their experiences. Popular does not always equate to effective.

References:

http://reefkeeping.com/issues/2007-03/rhf/index.php

http://www.reefkeeping.com/issues/2002-06/fm/feature/

What brand of heater should I buy for an 75gallon coral reef tank

You can choose one here.

protien skimmer with capacity from 2m3/hrs to 8 m3/hrs